How Shuttle & Stacker Crane Solution Work?

Huaruide Shuttle & Stacker Crane Solution system consists of shuttle type racking system, stacker crane, raido shuttle, conveyor system, management and controlling system. The storage and retrieval operation needs cooperation of stacker crane and shuttle.

When the stacker crane receives inbound order sent by WMS(Warehouse Management System), the stacker crane runs to the a bay which has a free child shuttle and load the child shuttle on its lifting platform, and transfer it to defined bay, once the stacker crane finish movement of child shuttle, it will go back to conveyor and take the pallet on its lifting platform. Then the stacker crane will put the pallet on the end bay which already has child shuttle. The child shuttle will load the pallet inside of bay and return to original position. Usually, the same SKU will inbound at the same time, so the stacker crane doesn’t need to move child shuttle frequently.

When the stacker crane receives outbound order, the stacker crane will transfer child shuttle to the defined bay first, the child shuttle will go inside, loading pallet and leaving it at the end of bay. The stacker crane will take the pallet on its lifting platform and put the pallet to the conveyors. Then the pallet will be sent to outbound station by conveyor lines.

Shuttle & Stacker Crane System consists of

• Shuttle type storage rack

• Conveyor lines

• Stacker crane

• Controlling System

• Software (WMS, WCS, RF)

Specification for Huaruide Shuttle & Stacker Crane System

• Maximum weight capacity: 1.5 tons.

• Stacker crane height: 5-15m

• Horizontal speed: 0-160m/min

• Vertical speed: 0-90m/min

• Child shuttle speed: 60m/min

• Conveyor line speed: 0-12m/min

• Pallet size: 800-2000mm*800-2000mm

• In/Out Throughput: 30 pallet/hr

The Benefits of Huaruide Shuttle & Stacker Crane System

• Extremely money-save automatic solution

The solution uses the least equipment to realize full automated storage and retrieval. Usually it only need to use one set of stacker and child shuttle with a short conveyor line which can fulfill automatic storage and retrieval function. So it is the first choice in low budget situation.

• High Space utilization in small footprint area

This solution is a kind of high density storage solution, the distance between pallets in the same bay is less than 50 mm, and the space between two layers of pallets is very less which can also raise storage capacity by saving height. The whole warehouse can storage pallets beside stacker crane aisle, so the maximum storage space utilization can reach up to 95% of total area.

• Safety and reducing mechanical injury

Due to it is labor free solution, it is no need to use operator work inside the storage area, and customer should not worry about the safe of their labor.

• Flexible to arrange position to every pallet.

The system is controlled by Huaruide WMS, each pallet is visual in the system, and operator can arrange the pallet to defined position through computer.

Jiangsu Baozong& Baoda Pharmachem: one set of shuttle & stacker crane takes charge of 1584 pallets

Jiangsu Baozong& Baoda Pharmachem Co., Ltd (BZBD), established in 2006, is a well-known Pharmaceutical company in China. It was started with its predecessor Shanghai Baoda Veterinary Pharmaceutical Co., Ltd in 1979 and Shanghai Baozong Pharmaceutical Co., Ltd in 1988.

BZBD’s ASRS is design for chemical raw material’s retrieval and storage. Regard to customer’s need, only one SKU will be stored in the warehouse, low-frequency of inbound and outbound, and need the most cost efficiently solution.

Configuration

This project includes the design, engineering, integration, installation and commissioning of the following automated systems:

• 14.4 meters stacker crane

• 1 pc of radio shuttle

• 1 set of pallet dispensers.

• Conveyor line

• Software (WMS, WCS, RF)

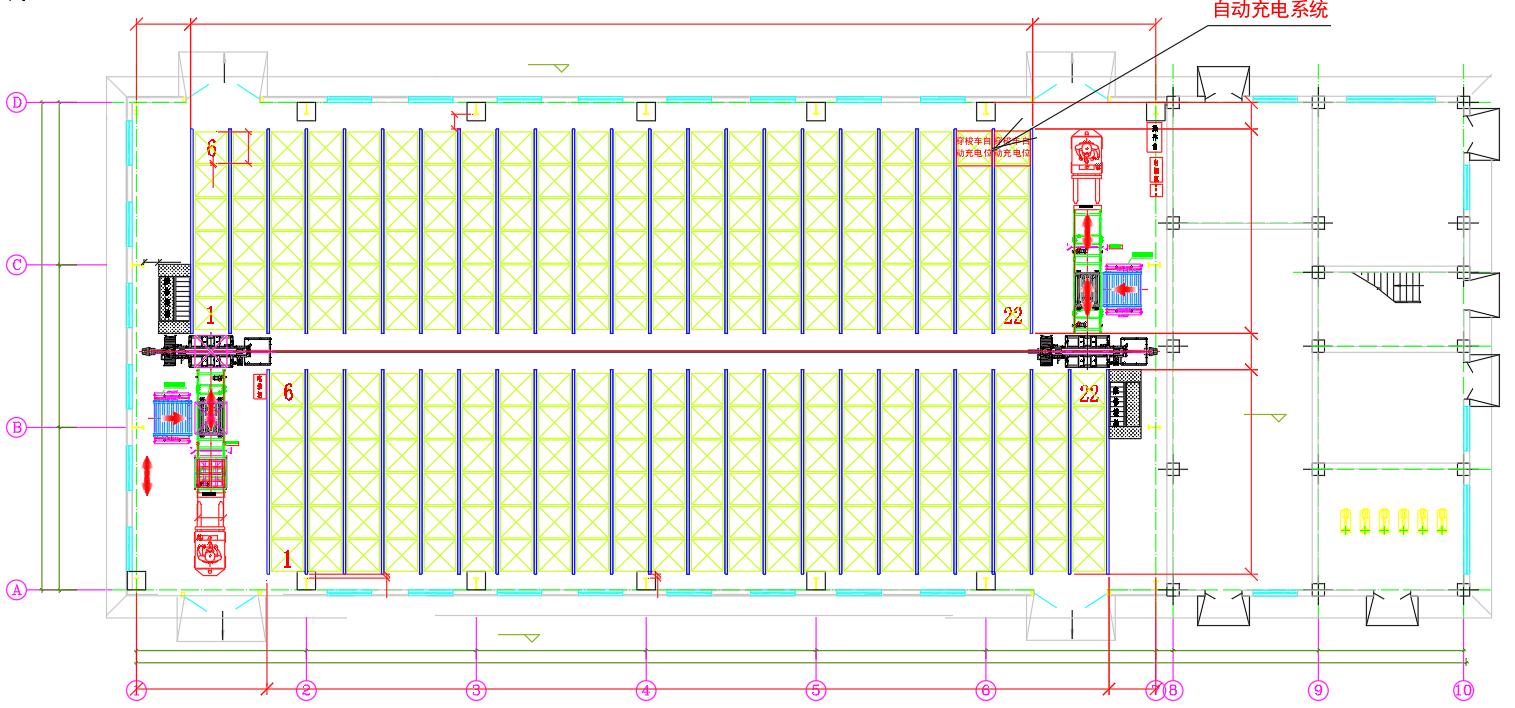

Top View of BZBD Stacker Crane and Radio Shuttle Solution

Advantages for the BZBD Pharmacy

The whole system is only using 1 set of stacker crane and radio shuttle, the least equipment and fulfill automated system, which means cost-effective. However it can full suit customer’s need, to utilize the biggest space to store pallet. The automation of all processes and the implementation of management software WMS have all allowed to meet their goals of increasing productivity and improving customer service with the utmost efficiency at the lowest possible cost.

Technical Data:

| Storage Capacity | 1584 pp |

| Height | 14m |

| Type | Clad-Rack ASRS |

| Pallet Size | 1200*1000 |

| Stacker Crane Qty. | 1 |

| Throughput | 30pallet/hour |

Gallery

Video

Post time: Jun-05-2021