How does Huaruide High-Density Mother-Child Storage Solution Work?

Mother-child shuttle system as known as shuttle-based ASRS has been having a bit of a moment from the last few years due to its extensive adoption in warehouses and order fulfillment operations. This technology utilizes the capacity of the warehouses in cubic feet over the earlier means where it used to utilize its capacity in square feet. It is designed to optimize the space used within the warehouses in order to obtain a higher level of productivity and efficiency. This system integrates the automated hardware with the software for the accurate picking and replenishment process. This results in a reduction of inventory level and material handling inconveniences while increasing the productivity and accuracy of the warehouse as compared to the manual storage systems.

This system is a fully automated and equally versatile storage and retrieval mechanism for multi deep pallet storage. It consists of a Mother shuttle powered by bus bar, which runs on a track perpendicular to the pallet storage in the racking system. It has a pallet shuttle as known as child in it which performs the function of storage and retrieval. This system is integrated with vertical lifts that carry the load to its destined position. Once the vertical lift reaches its designated position, the mother shuttle reaches there along with the child. The child takes the load and gets inside the Mother shuttle to again move on the track in order to reach the next destination. Retrieval of loads also happens through the same process.

Mother-Child Shuttle Storage Solution Consists of

• Shuttle type Storage rack

• Conveyor lines

• Mother shuttle

• Child shuttle

• Pallet Lift

• Layer transfer(optional)

• Buffer conveyor for per layer (optional)

• Controlling system

• In/outbound station

Specification for Huaruide Mother-Child Shuttle Storage Solution

• Maximum weight capacity: 1.5 tons

• Maximum rack height: 30m

• Mother shuttle speed: 0-160m/min

• Child shuttle speed: 0-60m/min

• Pallet Lift speed: 0-90m/min

• Conveyor line speed: 0-12m/min

• Pallet size: 800-2000mm*800-2000mm

The Benefits of Mother-Child Shuttle Storage Solution

• High-density storage, the utilization of storage area reach to 95%

• Increase working efficiency

• Better Inventory management

• Flexibility and modularity

• High-speed stable storage/retrieval operation

• Reduction in quantity of out of date and damaged pallets

• Ease of operation and maintenance

• Minimize employee safety risks involved with forklift operations

Baladi Frozen Automated Storage & Picking System in Israel: 14509 Pallet in -30℃ Cold Storage Warehouse

Baladi is a manufacturer, importer, distributor and marketer of meat, fish, vegetbables and other frozen products. The company is establishing a new logistic center on a freenfield at Timurim industrial park, Kiriat Malakhi, Israel.

Baladi’s new logistic center is designed for receing (free and bonded), storage, order picking, distribution and other activities such as production, company headquarters, etc. It has been decided to implement in the logistics center an automated system based on carrier & shuttles for frozen pallets, including an order picking system for frozen catons.

Operation Buildings with Four Floors

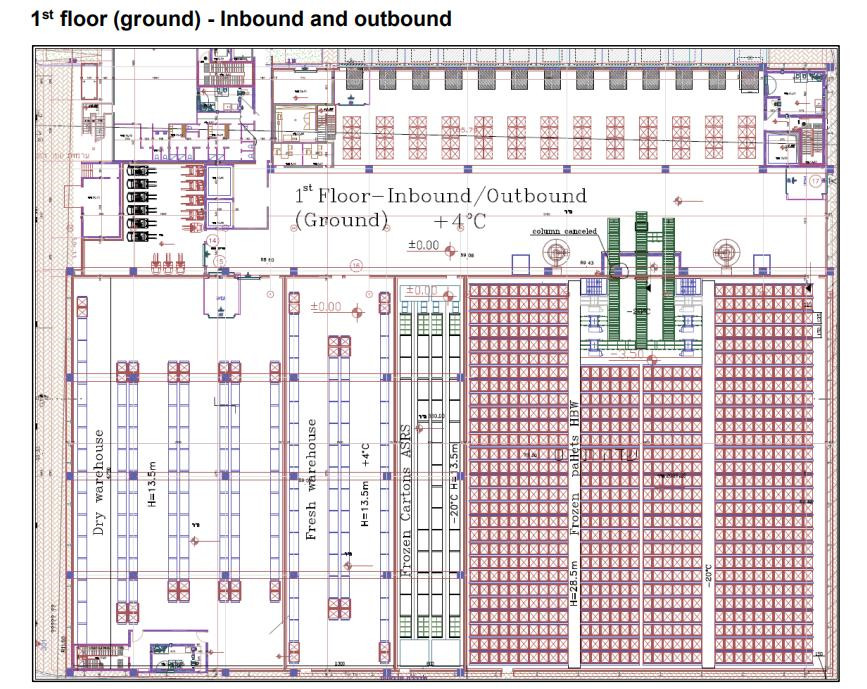

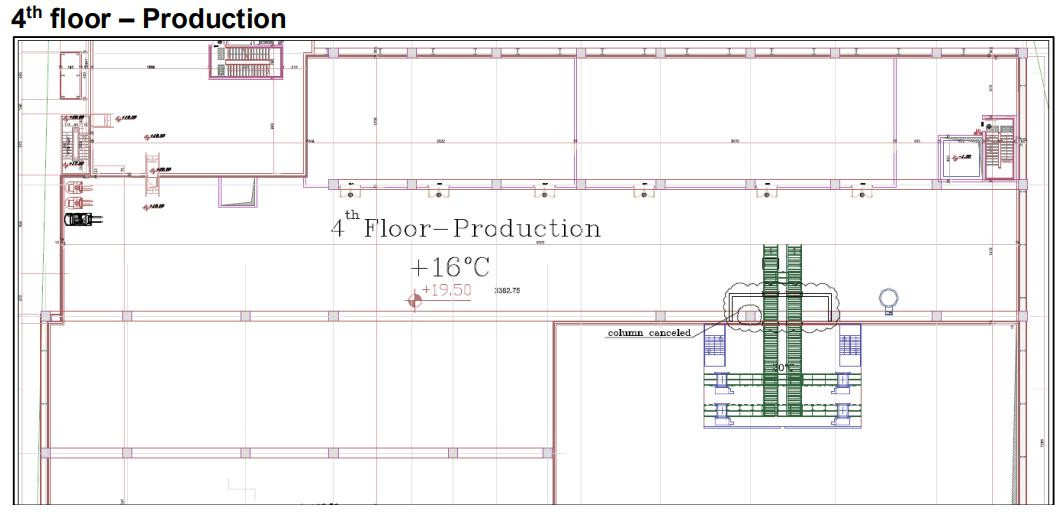

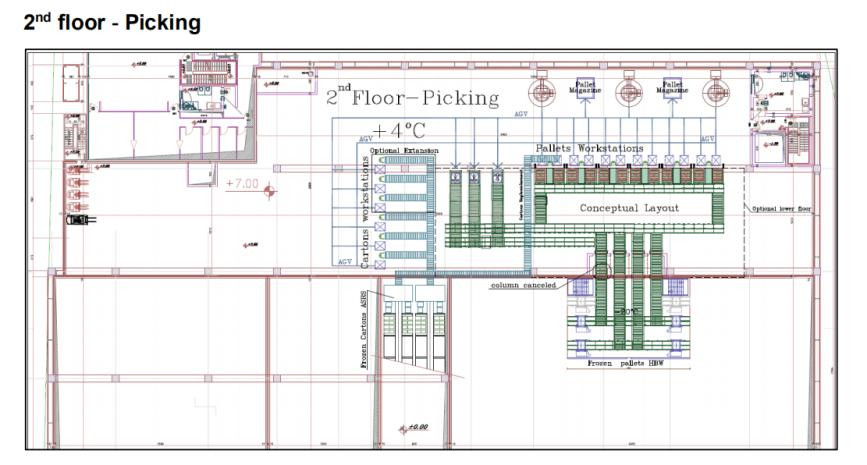

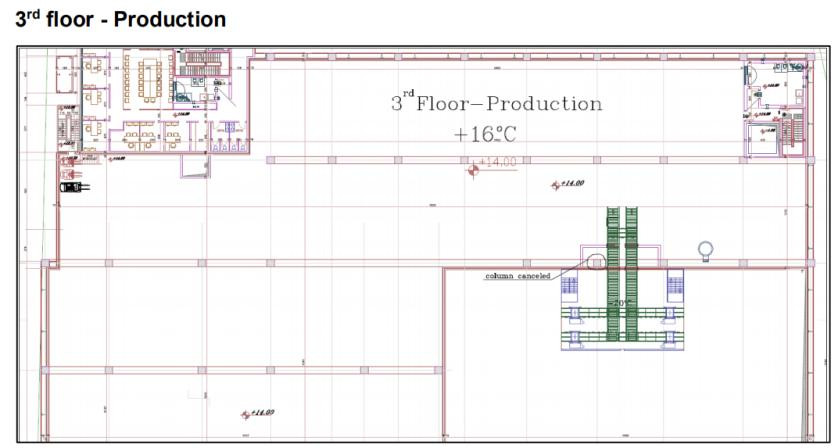

The building consists of 4 building floors connecting at each level to the frozen pallets high bay warehouse (HBW). Connecting at the 1st floor to receiving and distribution gates; connecting at the 2nd floor to a free standing cartons warehouse & picking area; connecting at the 3rd & 4th floor to a production area.

This project includes the design, engineering, integration, installation and commissioning of the following automated systems:

• Automated frozen (-20℃) pallets storage and retrieval system based on shuttle technology in free standing high bay warehouse for all floors (hereinafter: HBW).

• Picking system for pallets at the 2nd floor - picking (+4℃).

• Automated frozen (-20℃) cartons storage and retrieval (hereinafter: ASRS) based on miniload technology on free standing HBW.

• Picking system for cartons at the 2nd floor- picking (+4℃).

• Automated Guided Vehicle system (hereinafter: AGV) at the 2nd floor-picking system for the transfer of empty pallet and order pallets.

• Control system for the operation and integration of the automated system (WCS + MFC).

All the system and sub-systems included in this proposal will be apadted to operate in the temperateure of each zone +4℃/-20℃ as required, including all auxiliary equipment linked to the systems mentioned in this project.

Advantages for the Customer

The construction of the logistic center carefully adapted to suit their needs, the use of cutting-edge technology in storage system, the automation of all processes and the implementation of management software WMS have all allowed Hayat Kimya to meet their goals of increasing productivity and improving customer service with the utmost efficiency an at the lowest possible cost.

The following are some of the advantages experienced immediately

• Reduction in the time needed for all goods movement operations.

• Large increase in the number of movements of goods in and out of storage.

• Uninterrupted operation: The system of entry and dispatch is in operation 24hours a day, seven days a week, and in peak periods, is capable of handling up to 400 incoming pallets/hour, and 450 outgoing pallets/hour, with an average of 6500pallets coming in and 7000 pallets leaving each day.

• Integrated goods receipt, preparation and dispatch processes thanks to the management WMS.

Gallery

Baladi High-Density Storage Mother-Child Shuttle, Israel

| Storage Capacity | 14509pp |

| Height | 28.5m |

| Type | Stand-alone High-density Solution |

| Pallet Size | 1200*1000 |

| Mother-Child Shuttle Qty. | 38 |

| Throughput | 850 pallet/hour |

Post time: Jun-05-2021