Four-Way Shuttle

How does Huaruide four-way shuttle work?

Huaruide four-way shuttle is able to move in 4 directions on the storage lanes and main lanes. In this way the shuttle can change lanes without operation of forklift, greatly save labor cost and improve warehousing efficiency.

Huaruide four way radio shuttle system usually consists of racking system, radio shuttle, lift, conveyor and WMS/WCS system. Conveyor line is placed in front of racking system for picking and receiving of pallets. Lift will transport radio shuttle and pallets from ground to different layers. With instruction of WMS/WCS system, radio shuttle is able to automatically pick and deliver pallets to appointed position inside racks, which could realize automatic storage and retrieval of goods in warehouse.

How does Huaruide four-way shuttle make logistics easy?

Four way shuttle can move in 4 directions, which means it is more flexible, allowing to make more storage strategy. Multi shuttles can work on the same under the communication technology to fulfill any required throughput in the peaking period. Due to the WMS system, the order can be done with 100% accuracy with high speed, avoid the mistakes caused by manual operation.

Features

• Four way travelling, and then it can fulfill 6 direction movement, front-back, left-right, up-down movement, cooperating with lift.

• Four way shuttle can reach any place of warehouse (or other transportation site) according to customer's demand, make maximum use of storage space of warehouse, suitable for special type warehouse. Cooperating with lift, it can reach any height required by the customer.

• The small size of four way shuttle lower every layers height, make the full utilization rate of warehouse space.

• All equipment products and control components in the shuttle are standard, mature and reliable product accessories. The control system adopts simple and stable control components, uses specific algorithms, and combines the simple and solid mechanical structure of the shuttle itself to achieve stable, accurate, fast and reliable operation.

Benefits

• Greatly increase storage capacity, which is 3-4 times large than traditional racking system.

• Cost effective and time-saving, reduce land and labor cost

• Fully automatic, low level of risks or damage to the equipment and operator.

• Self-designed WMS/WCS system to well match shuttle system.

• Available to meet various storage capacity demand with adjustment of shuttle quantity.

Parameters

| Item | Parameter | Remark |

| Size L*W*H | 1100L*980W*150Hmm | 1200W*1000D Pallet |

| 1200L*980W*150Hmm | 1200W*1100D Pallet | |

| 1300L*980W*150Hmm | 1200W*1200D Pallet | |

| Characteristic | Four-Way Travelling, intelligent control | |

| Load Capacity | 1500kg | |

| Weight | 400kg | |

| Lifting Stroke | 40mm | |

| Travelling Driving | Motor | |

| Braking Model | Power-cut Braking(Servo) | |

| Driving Motor | DC48 V | |

| Travelling Motor Power | 1.2kw | |

| Lifting Motor Power | 0.75kw | |

| Positioning | ±2mm | |

| Autonomous Obstacle Avoidance | Dispatch, Photoelectric Sensor, Distance Monitor(Optional) | |

| Travelling Acceleration | 0.3m/S2 | |

| Travelling Speed( Empty) | 1.5m/s | |

| Travelling Speed(Full) | 1.2m/s | |

| Aisle Change Period | ≤5s | |

| Lifting Period | ≤5s | |

| Communication | WIFI | |

| Power Supply | Battery | |

| Charging Method | Manual/Automatic | |

| Battery Capacity | 48V 36AH/45AH/60AH | 1000D/1100D/1200D Pallet |

| Charging Period | 1.5H~2H | |

| Battery Type | Lithium Iron Phosphate Battery | |

| Recharging Cycle | Over 2000 time(100% Charging) | |

| Battery Life | Over 2 years | |

| Daily Working | 8 hours | |

| Position | Laser | |

| Driving Motor | Servo Motor | |

| Operation Method | Online/Single/Manual/Manintanence | |

| Protection | Abnormal temperature alarm/collision protection | |

| Color | Red/white | Customized |

| Electron Component | Supplier | Remark |

| PLC | Schneider | |

| I/O Module | Schneider | |

| Switch Power | MeanWell | |

| Air Switch, Contactor | Schneider | |

| Sensor | P+F/Panasonic | |

| Indicator light, switch button | Schneider | |

| Wifi Client | MOXA | |

| Site Operation Terminal | Schneider | Optionals |

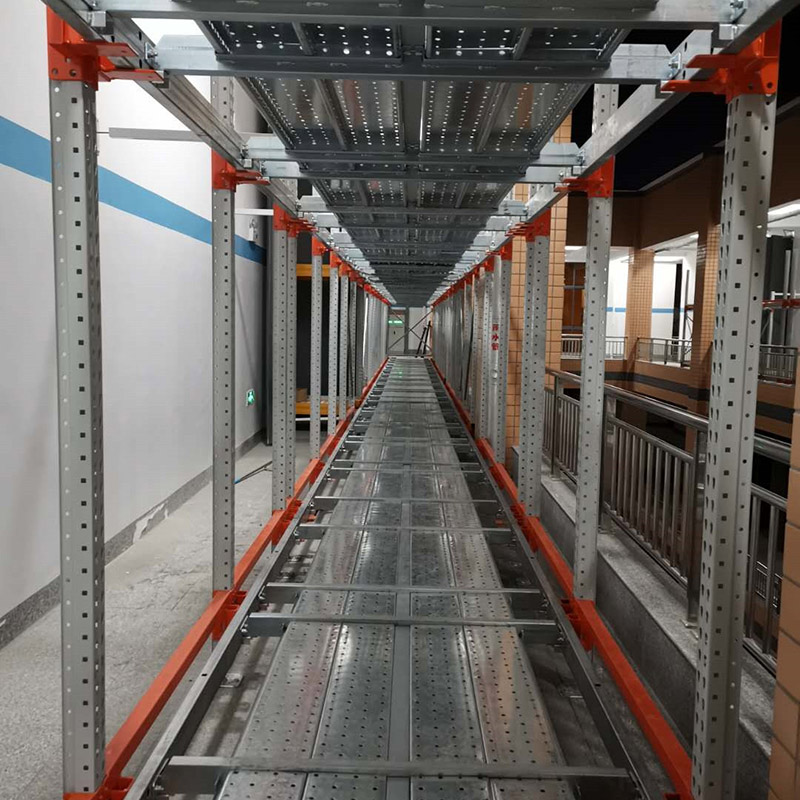

Gallery