What is Clad-Rack Warehouse?

Clad-rack warehouse can be made up of any type of storage system as their main feature is for the racking to form part of building structure.

In this system, the racking not only supports the load of the stored goods, but also the load of the building envelope, as well as external forces such as wind or snow.

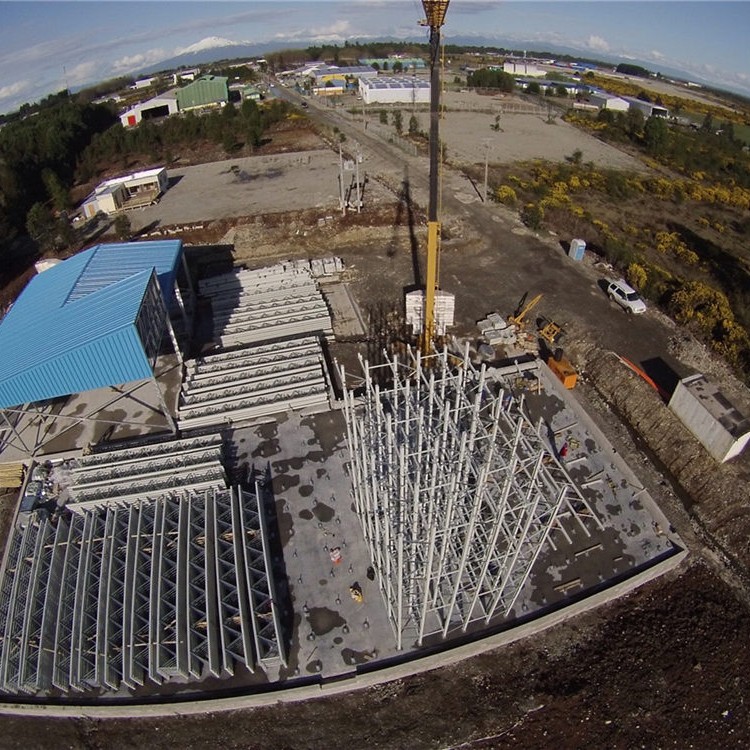

This is the reason why clad warehouses represent the concept of optimum use of a warehouse: in the construction process, first the racking is assembled, and then the building envelope is built around this structure until the warehouse is complete.

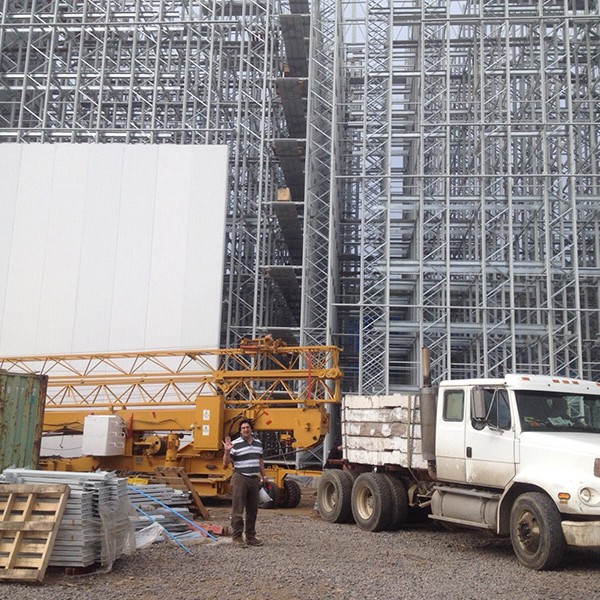

Most clad rack buildings are equipped with automated systems and robotic equipment for the handling of goods, especially of if they are multitier. The maximum height of clad-rack buildings is limited by local standards and by the reach height of stacker cranes or fork-lift trucks. This said, warehouses of more than 40 m high can be built.

The Benefits of Clad-Racking Warehouse

• Full use of the space

The warehouse is designed at the same time as the racks and only occupies the space required, without intermediate pillars that influence their distribution.

• Maximum height of the construction

You can build to any height, it only depends on local regulations or the scope of the handling means which are used, being able to exceed 45m high (which would be complex and expensive in traditional construction).

• Simpler construction

The entire structure is assembled on a concrete slab of suitable thickness to achieve uniform distribution of the forces on the foundation; there isn’t a high concentration of loads.

• Less time for completion

Once the slab is built, the entire structure and cladding are progressively and concurrently installed.

• Cost savings

As a general rule, the cost of a clad-rack warehouse is less than the more traditional racks. The greater the construction height, the more profitable the clad-rack system.

• Minimal civil works

It only requires the construction of the slab on the ground and, in some cases, a waterproof wall between one and two meters high. In which case the operations area needs to be expanded for receipt and dispatch, a traditional

Building can be built, but of sufficient height without reaching the total height of the warehouse.

• Easily removable

Being a structure formed by standard rack elements that come pre-assembled or bolted, they can be dismounted with ease and a high percentage of components recovered.

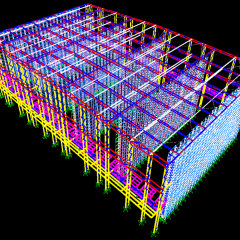

Cladding Structure consists of

• Roof truss

• Side-wall structure

• End-wall structure

• Wall, roof sheet and accessary

• Staging area building

Specification for Huaruide Clad-Rack Type Unit Load AS/RS

• Maximum weight capacity: 3 tons

• Stacker crane height: 5-45m

• Horizontal speed: 0-160m/min

• Vertical speed: 0-90m/min

• Conveyor line speed: 0-12m/min

• Pallet size: 800-2000mm*800-2000mm

Specification for Huaruide Clad-Rack Type Mother-Child Shuttle Storage

• Maximum weight capacity: 1.5 tons

• Maximum rack height: 30m

• Mother shuttle speed: 0-160m/min

• Child shuttle speed: 0-60m/s

• Pallet Lift speed: 0-90m/min

• Conveyor line speed: 0-12m/min

• Pallet size: 800-2000mm*800-2000mm

Alibaba Clad-Rack Type United Load ASRS: the biggest warehouse in Asia with nearly 100,000 pallets

Alibaba Group Holding Limited, also known as Alibaba Group and Alibaba.com, is a Chinese multinational technology company specializing in e-commerce, retail, Internet, and technology. Founded on 28 June 1999 in Hangzhou, Zhejiang, the company provides consumer-to-consumer (C2C), business-to-consumer (B2C), and business-to-business (B2B) sales services via web portals, as well as electronic payment services, shopping search engines and cloud computing services. It owns and operates a diverse portfolio of companies around the world in numerous business sectors.

To deal with mountains of orders, it request the biggest storage capacity in the fixed footprint area. Due to the position is near sea in Ningbo city, where is threaten by typhoon and heavy rain frequently. The traditional steel structure building is hard to suffer in extreme weather with high over 30 m. The clad-rack structure become the only solution.

Since it is an e-commerce company solution, to deal with large number of SKU, the stacker crane is the best choice. So after many rounds discussion with customers. Clad-rack type united load ASRS is determined as the final solution for this project.

The Biggest Storage Capacity in Asia

Alibaba Ningbo Clad-Rack Warehouse’s Storage reach to over 100,000 pallet locations with 34 m height inside (building height 38m), totally 17 layers, and 102 rows for storage area. It estimates 70,000 tons when the full storage is used.

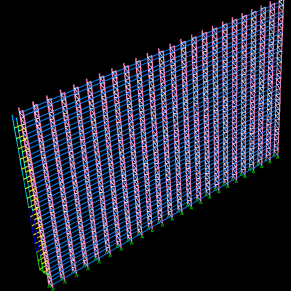

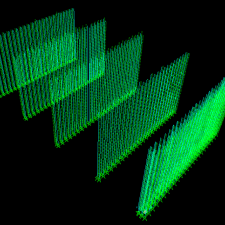

Rack Structure Safety Examination: Finite Element Analysis

The rack calculation is made by the most advanced finite element analysis software. According to the requirements of fire isolation zoning, the model of hot-rolled steel frame was established, and the overall collapse accident could be avoided after the cold-rolling frame lost its supporting role due to fire or other accidents of the warehouse structure.

Based on the design concept of probabilistic limit state, only the combination of dead load, snow load, wind load and seismic action is considered in this kind of working condition.

Finite Element Analysis for Racking Structure

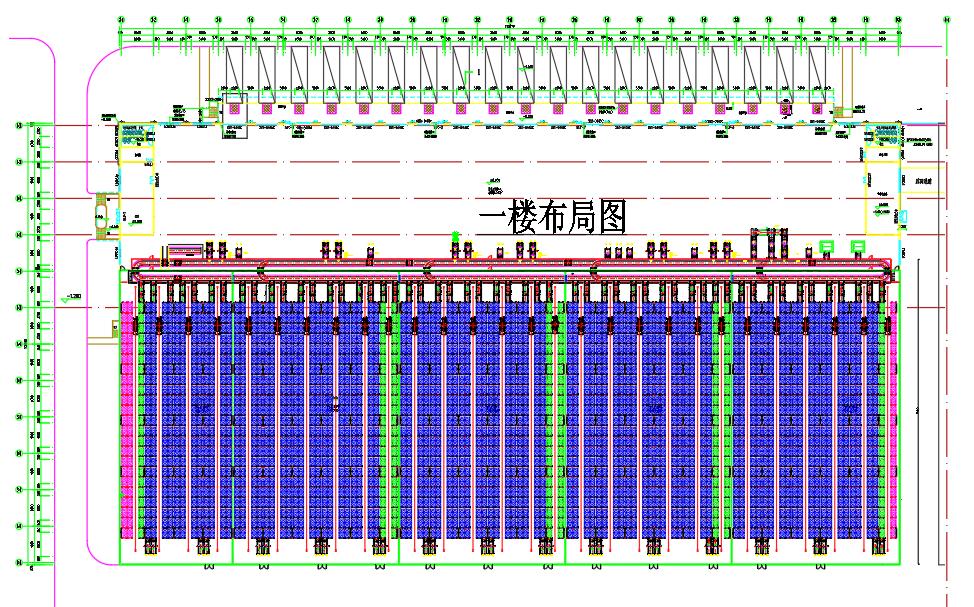

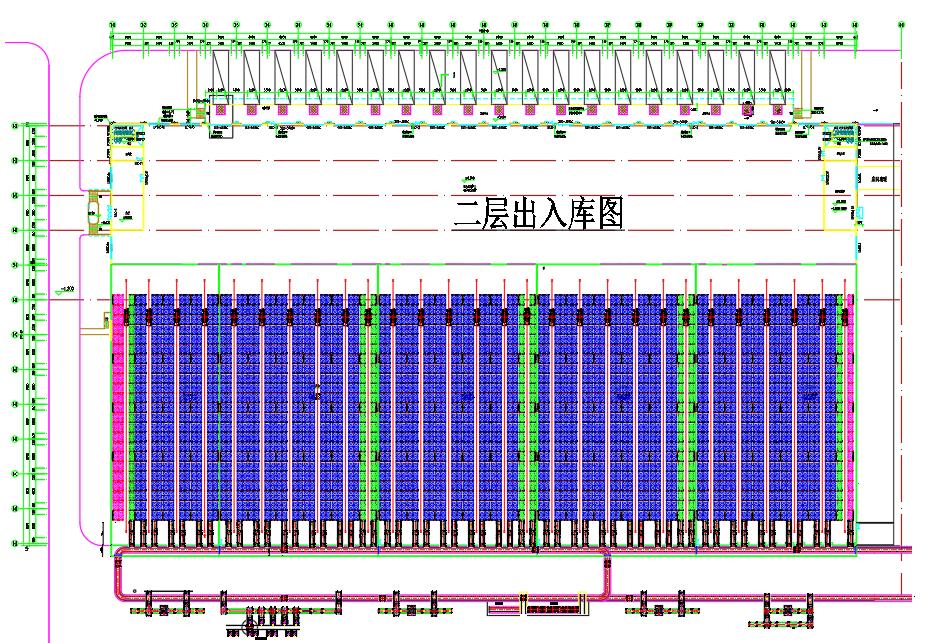

Configurations

The building consists of 2 floors, pallet inbound and outbound from the 1st floor, picking operation will be done on the 2nd floor.

This project includes the design, engineering, integration, installation and commissioning of the following clad-rack automated systems:

• 38 meters height racking

• Cladding includes wall sheet, side and end wall, roof, and other accessories.

• 28 sets of stacker crane ASRS

• 40 sets of RGV with ramping system travelling in 2 loops for pallet take and put.

• Control system for operation and integration of the automated system (WMS, WCS, RF System).

1st floor (ground) – outbound & Inbound

2nd floor – Picking

Advantages for Alibaba Group

• High space utilization

Because there is no pillar inside, the space utilization is 25% upper than stand-alone warehouse.

• Maximum height

The 38 meters height is much higher than normal steel structure building which is usually around 24 meters.

• High-strength structure

The site is near sea, so typhoon is very frequent, which requires high strength of building. In this project, every single upright gives support to the clad-rack warehouse, also anti-wind trusses is around to make sure the building stability.

• Cost effective

Over 30% cost was saved compared with building steel structure first and then install ASRS plan.

• High working efficiency

It can deal with 1400 pallet per hour, 14,000 pallet daily.

• Intelligent Management

Under the great pressure of larger quantity of pallet in/out, WMS can give 100% accuracy under the right operation. Besides, with application of WMS, each cases of product can be tracked

Gallery

Alibaba Clad-Rack Type United Load ASRS, Ningbo City

| Storage Capacity | 100,000pp |

| Height | 38m |

| Type | Clad-Rack ASRS |

| Pallet Size | 1200*1000 |

| Stacker Crane Qty. | 28 |

| Throughput | 1400pallet/hour |

Post time: Jun-05-2021