-

Stacker Crane

Stacker crane is the important storage & retrieval device in ASRS. It consists of the machine body, lifting platform, travelling mechanism and electric control system. With 3-axes movement, it travels in the lane of the racking system of the automated storage and retrieval system, carries cargo from the entrance of each lane of racking and put at specific location on the racking or picks the cargo from the racking and carries to the entrance of each lane.

-

Mother-Child Shuttle

The mother-child shuttle system is a fully automated and equally versatile storage and retrieval mechanism for multi deep pallet storage. It consists of a Mother shuttle powered by bus bar, which runs on a track perpendicular to the pallet storage in the racking system. It has a pallet shuttle aka child in it which performs the function of storage and retrieval. This system is integrated with vertical lifts that carry the load to its destined position. Once the vertical lift reaches its designated position, the mother shuttle reaches there along with the child. The child takes the load and gets inside the Mother shuttle to again move on the track in order to reach the next destination. Retrieval of loads also happens through the same process.

-

Radio Shuttle

Radio shuttle is a kind of high-density storage system in which a shuttle driven by an electric motor runs on rails inside the storage channels, replacing forklifts, considerably reducing operating times and enabling items to be grouped by channels rather than complete lanes.

-

Pallet Conveyor

Pallet Conveyor are designed to transport, accumulate a/o distribute goods to specific goods to specific locations during the logistics operations of a warehouse, a production center or between the two/ they achieve maximum process efficiency for inputs, outputs and in-house handling of unit loads.

Huaruide has implemented more than 100 conveyor systems, helping our customers fulfill their orders with accuracy and on-time delivery. Whether you are conveying individual products, full cases, or pallets, we can recommend the appropriate equipment, technology, and material flow layout. Our engineering team designs conveyor systems using 3D modeling tools, allowing you to visualize and simulate how your final system will operate

-

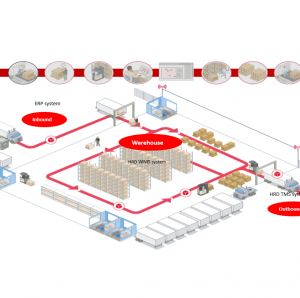

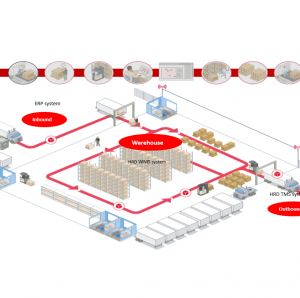

Warehouse Management System (WMS)

A warehouse management system (WMS) is a software solution that make business’ entire inventory visible and manages supply chain fulfillment operations from the distribution center to racking.

-

Pallet Dispenser

Pallet stackers and pallet dispensers replace manual handling of pallets in automated material handling systems. Pallet stackers do the work for you, placing used pallets in a stack for reuse or transport. Pallet dispensers are an integral part of most palletizing systems ensuring a pallet is always ready for a robotic or conventional palletizer to place products. Huaruide’s pallet dispensers and pallet stackers are a great way to reduce labor and improve productivity in your palletizing systems.

-

Mobile Rack

Electric Mobile Racking, is one of the high-density racking system. It only requires one channel, with very high space utilization. Through the electric motor driving and frequency control, make the racking from start to running all in stable situation, the security get guaranteed. According to the structure types, there are rail type and without rail type.

-

Pallet Lift

The fixed lift is the key device for the fully automated storage system, the function is to move the pallet up and down. HUARUIDE vertical lift consists of machine body, lift platform, conveyors, wire rope traction power system, balancing system and control system. Seamless connection with the master control system can be realized by it.

-

Rail Guided Vehicle

Rail Guided Vehicle (RGV), also called Sorting Transfer Vehicle (STV) or Shuttle Loop System (SLS), is a complex automated unit load handing system. The system consisted of self-proplled, self-steering vehicles moving on circuit aluminum rail system, by setting up multiple pick-up and drop-up stations, manufacturing, storage and picking process can be performed efficiently and accurately.

It can be used to move unit loads with various sizes, whether in boxes/containers or pallets, load range from 30kg to 3tons. Its aluminum rails can be in the form of loop or in a straight line. The transfer mechanism can be roller based or chain-based.

Through vehicle-to-vehicle communication, the vehicles are maintained optimal distance from each other, preventing collisions and maximum inbound & outbound throughput.

This RGV system from Huaruide is high dynamic system for transporting a huge range of different unit loads while achieving excellent throughput rates. It is here in particular that the interfaces to the adjoining warehouse and materials handling installations play a crucial role.

-

Four-Way Shuttle

Four way radio shuttle system is automated high-density storage and retrieval system for the handling of palletized goods. It’s an optimal solution for the storage of goods with mass quantity and small SKU, widely used in the industry of food&beverage, chemical, third party logistics etc.

-

Layer Transfer

The function of the layer transfer is to lift up and down the mother-child shuttle and transfer it at different layers when a few mother-child shuttle but more layers. Usually it locates at the end of rail of high-density storage system. It consist of the machine frame, mother shuttle platform, wire rope traction power system, balancing system and controlling system. Seamless connection with master control system can be realized by it.