China Wholesale Warehousing And Distribution Solutions Suppliers - Stacker Crane – Huaruide

China Wholesale Warehousing And Distribution Solutions Suppliers - Stacker Crane – Huaruide Detail:

How does Huaruide Stacker Crane work?

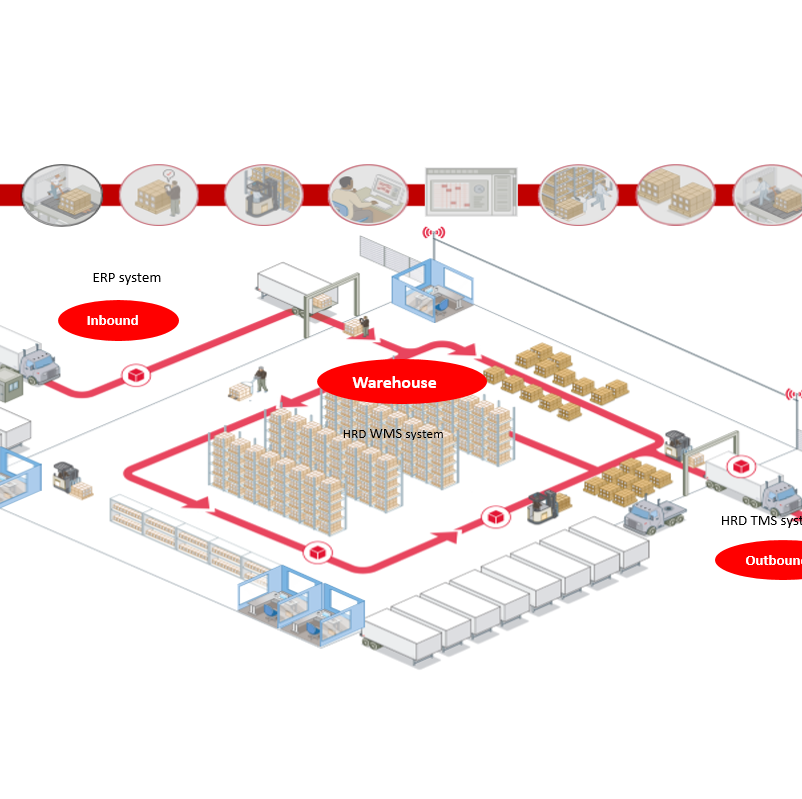

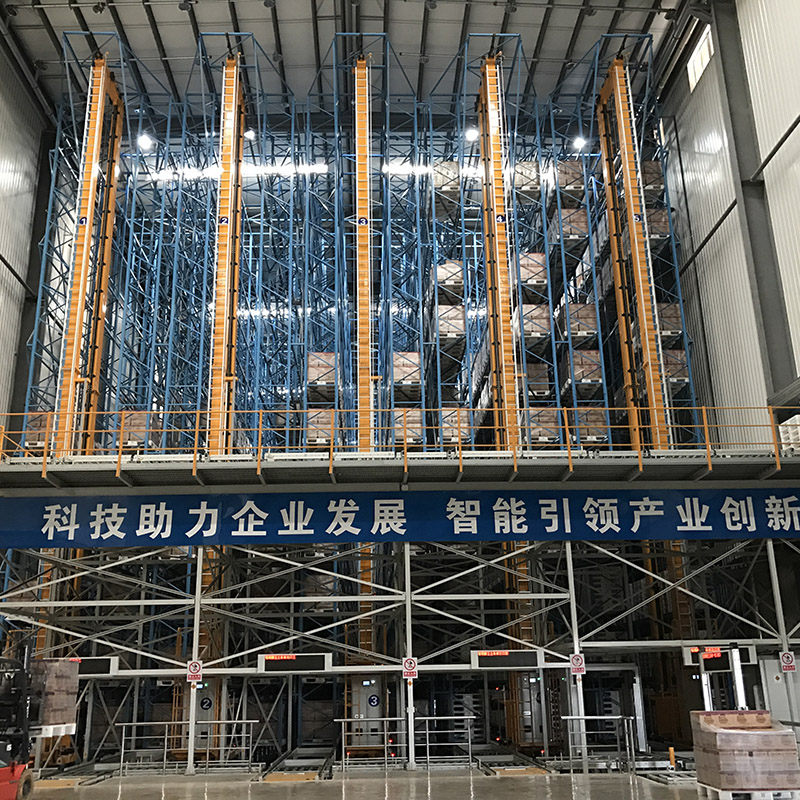

Huaruide stacker crane based united load ASRS, it features one or more narrow aisles of storage rack structures in existing building or a clad rack warehouse. The structure can reach up to 40 meters. Our storage and retrieval machine (SRM) travels between the racking both in X-axis, and Y-axis, instructed by WMS which provides a rapid access to allocated pallets and other bulky loads in a secured, high-density and energy efficient storage system. Usually, the system contains one SRM per aisle. But in case it is a slower system, one SRM can be allocated to 2 or multiple aisles.

How does Huaruide Stacker Crane make logistics easy?

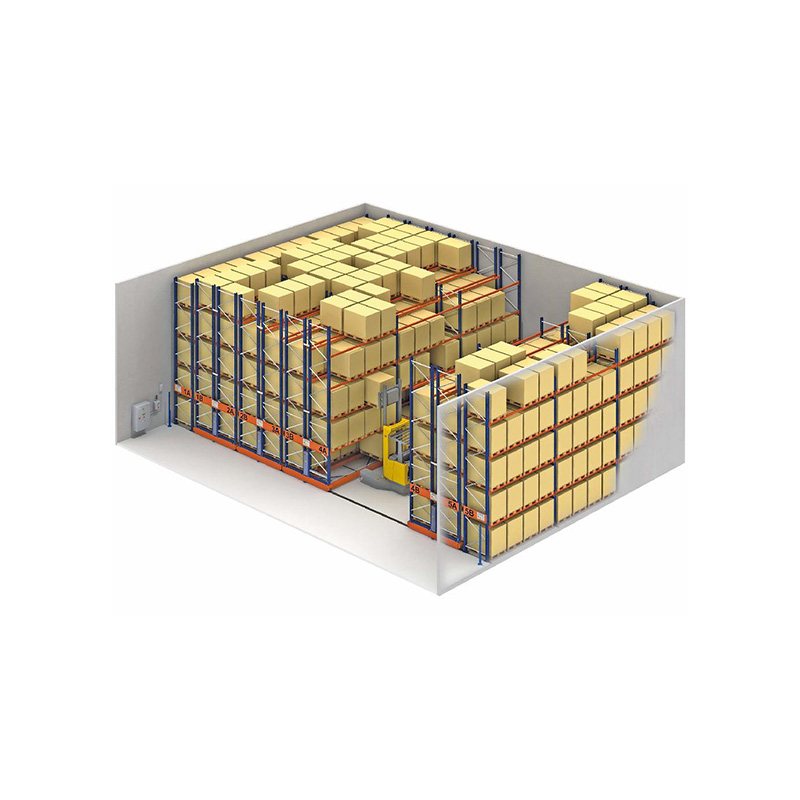

Compared with traditional manual rack warehouse, Huaruide stacker crane solution can reach more pallets by extending the height of warehouse with limited area. The logistics will go very fast by setting stacker crane speed, and the machine doesn’t need rest.

For some extremely environment, for example -30 ℃ cold storage warehouse, using stacker crane can save energy by less time of opening heat-resistant door, and it can fulfill non people work inside, so it is safe solution for operator.

From long term viewing, using stacker crane must save money by less labor, but more efficient. Also, the system is controlled by Warehouse Management System (WMS), which providing 100% visibility and accuracy, avoid the loss by operator’s mistakes. WMS can track inventory locations and directs the movement of loads while fully integrating with intelligent software platforms.

Features

• Compact structure with high strength and good rigidity.

• Imported motor and electric components, reliable and stable.

• Easy operation HMI, modular structure, network communication, automatic and high-efficient.

• Falling protect, over-speed protect, and stalling protect, protect from all aspects.

• Seamless connection of the ground guide rail, dedicated “T” shape rail for lift as lift platform rail, uniform clearance, high strength and straightness, good stability and low noise.

• Global leading fork technology, operating high efficiently and stably.

• Cable anti-swing mechanism, elegant appearance, winding prevention and safe.

• Built-in photoelectric sensor control mode make operation safe.

• 100,000 times of life span test has been done to give more assurance when operating it.

• It is more reliable as it is produced by Huaruide automatic CNC machine center.

Benefits

• Cost-efficient commissioning, transport and installation

• Minimization of spare parts inventory due to unique shared components concept

• Masts are bolt assembled in sections ranging up to 12m directly on site

• Automation of the entry and exit operations of products.

• Controls and updates the inventory.

• Eliminates manual management mistakes.

• These systems can be adapted to special working conditions such as freezing temperatures -30 °C, extreme humidity or special features including the possibility of increasing standard working speeds.

Parameter

• Maximum Height: 45m

• Maximum Load weight 3 tons

• Vertical Speeds: up to 2m/s

• Product Range: single and double mast

• Minimum Operating Temperature: -30°C

• Speed of Operation: up to 3m/s

• Throughput: 20 – 45 double cycle/h

Applications

• Distribution centers

• Production storage

• Buffer storage

• Chilled or frozen storage (-28°C)

• Stainless steel applications in the food & beverage sector (i.e. meat industry)

Gallery

Product detail pictures:

Related Product Guide:

As a way to finest meet up with client's wants, all of our operations are strictly performed in line with our motto "High Quality, Aggressive Price, Fast Service" for China Wholesale Warehousing And Distribution Solutions Suppliers - Stacker Crane – Huaruide , The product will supply to all over the world, such as: Georgia, Roman, Istanbul, Many kinds of different solutions are available for you to choose, you can do one-stop shopping here. And customized orders are acceptable. Real business is to get win-win situation, if possible, we would like to deliver more support for customers. Welcome all nice buyers communicate details of solutions with us!!

Reasonable price, good attitude of consultation, finally we achieve a win-win situation,a happy cooperation!