China Wholesale Pallet Storage System Quotes - Radio Shuttle – Huaruide

China Wholesale Pallet Storage System Quotes - Radio Shuttle – Huaruide Detail:

How does Huaruide radio shuttle work?

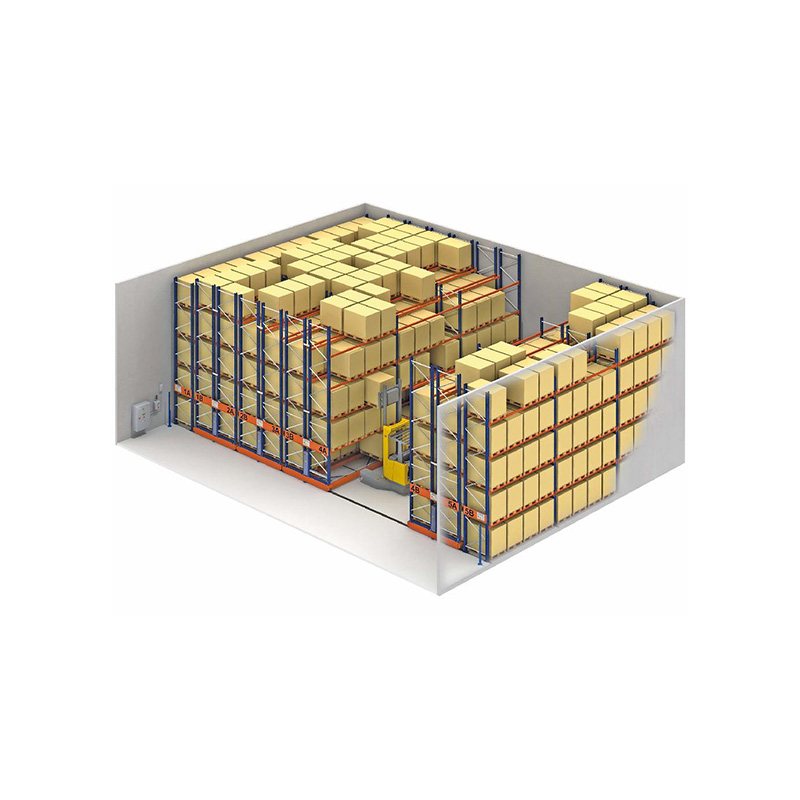

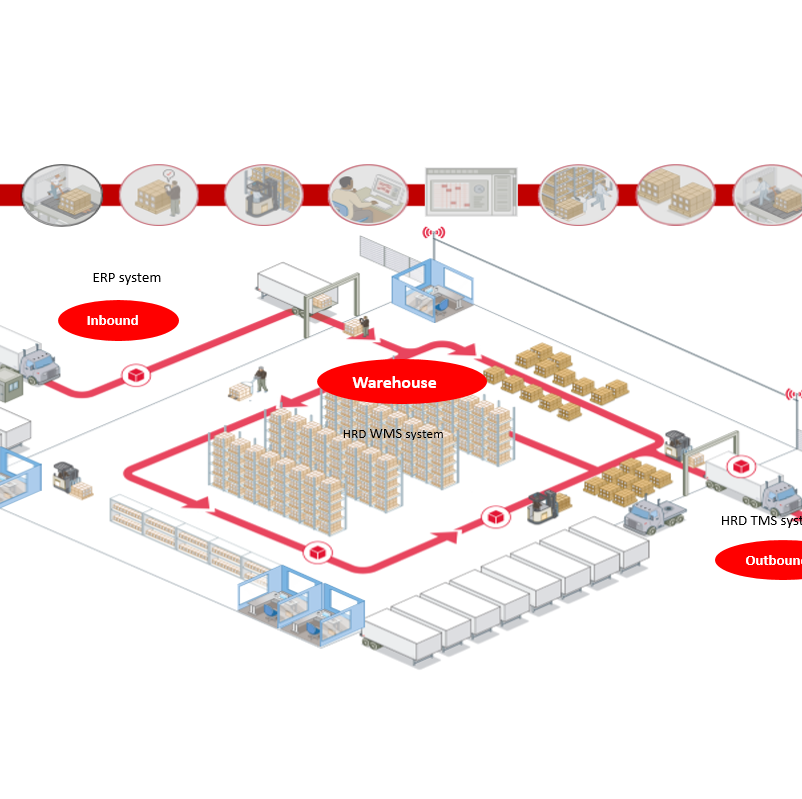

The working principle of the radio shuttle rack is similar to the drives in the rack, mainly because the structure of the reciprocating rack is very similar to the drives in the rack. The difference is that radio shuttle racks are smarter, faster, safer, and more accurate than commodity drive racks. The shuttle is operated by a shuttle. The forklift places the goods on the shuttle, which then sends the goods to the bottom of the shelf. The whole process is very safe and convenient. The space utilization and operating efficiency of shuttle shelves are very high, but because shuttles are required, similar to semi-automatic, the input cost of the shelves is relatively high. In order to facilitate the transportation of goods, the shuttle shelves are mainly suitable for a small amount of product storage and the operation of refrigerated shelves.

Radio shuttle rack allow you to maximize the full potential of your warehouse by dramatically increasing capacity, reducing operating costs, and increasing throughput, enabling you to truly maximize your warehouse space. It is also a solution that can bring huge benefits and attractive return on investment.

Features

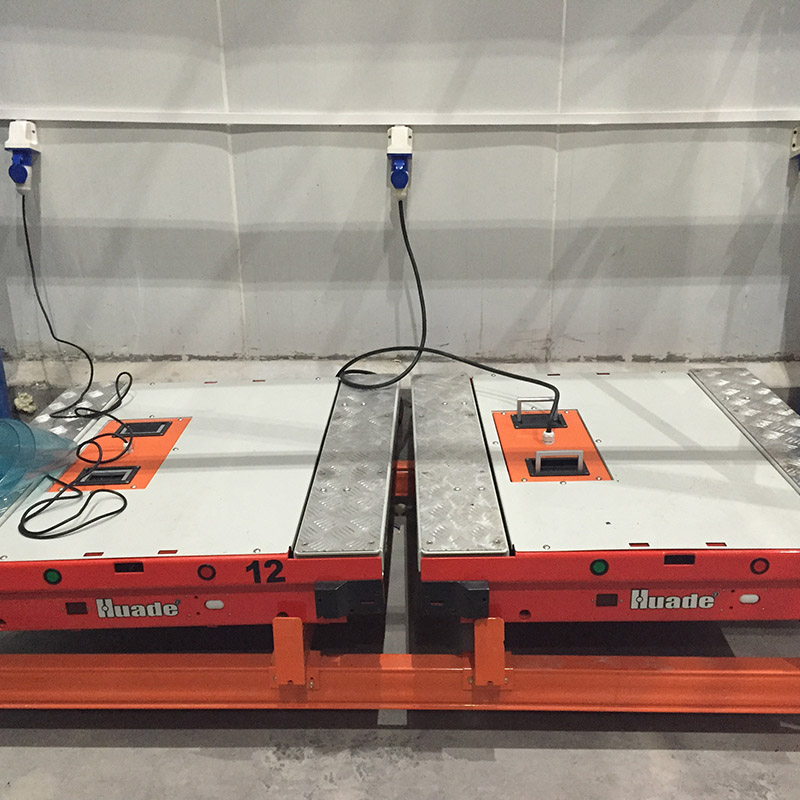

• High-performance lithium battery charge-discharge technology.

• High-performance imported motor, exclusive lifting technology 17 nos. of imported photoelectric sensors positioning technology.

• Excellent acceleration performance and operation stability.

• Global leading forklift anti-collision patent technology.

• Omni directional infrared anti-collision technology.

• Advanced smooth ON-OFF operation.

Benefits

① Bigger storage capacity:

• Narrow clearance between 2 pallets in the same lane.

• Minimal clearance between levels, maximum utilization of height space.

• No need to provide passage for forklift

② Higher throughput

• Reducing loading and unloading time are reduced, since the operator does not need to work inside the lanes.

• High speed movement inside of racking, 60m/min, faster than forklift in normal rack.

③ Cheaper

• The result of the benefits mentioned previously, together with the consumption of energy, is a reduction in costs, making Pallet Shuttle one of the most cost-effective compact storage systems.

④ Safety

• Due to the structure is built, forklifts do not need to drive into the lanes, avoiding the risk of accidents. And rack structure is seldom damaged, meaning maintenance is kept to a minimum.

⑤ FIFO or LIFO can be possible

Applications

• Food Production

• Cold Storage

• Garment Industry Warehouse

• Textile industry

• Pharmaceutical industry warehouse

• Logistics company

Parameter

|

Shuttle |

Item |

Specification |

|

1 |

Outside Dimension |

L1000*W953*H200mm |

|

2 |

Loading Capacity |

1000kg |

|

3 |

Travelling Drive |

Lenze Speed Reducer DC24V |

|

4 |

Walking Speed(Empty Load) |

Max. 1m/s |

|

5 |

Walking Speed(Full Load) |

Max. 0.75m/s |

|

6 |

Acceleration(Empty Load) |

0.5m/s2 |

|

7 |

Acceleration(Full Load) |

0.3m/s2 |

|

8 |

Travelling Positioning Accuracy |

±10mm |

|

9 |

Walking Driving Unit |

AMC50A8 |

|

10 |

Walking Control Mode |

Closed-loop servo a-service control |

|

11 |

Lifting Motor |

DC24V |

|

12 |

Lifting Time Duration |

≤5s, plate lifting |

|

13 |

Positioning Distance |

panasonic EQ34-PN |

|

14 |

Phototelectric Switch |

P+F/LEUZE |

|

15 |

Electrical Controling |

Siemens PLC S7-1200 |

|

16 |

Low Voltage Electrical |

Schneider |

|

17 |

Communication Method |

WIFI |

|

18 |

Battery |

DC24V/ Supercapacitor 400F / Charger in 3 phases 380V |

|

19 |

Propulsion Radius |

>70m |

|

20 |

Charging Time |

Therical 1 million times |

|

21 |

Charging Method |

Online automated charging |

|

22 |

Charging Temperature |

-25-60℃ |

|

23 |

Battery Replacement |

Automated Charging |

|

24 |

Safety Provision |

Mechanical Buffer block |

|

25 |

Operation Mode |

Automated / Manual Mode |

|

26 |

Environmental Temperature |

-5 ~ 40℃ |

Gallery

Product detail pictures:

Related Product Guide:

Our mission should be to turn out to be an innovative supplier of high-tech digital and communication devices by furnishing benefit added design and style, world-class manufacturing, and repair capabilities for China Wholesale Pallet Storage System Quotes - Radio Shuttle – Huaruide , The product will supply to all over the world, such as: California, Honduras, Birmingham, Our company covers an area of 20, 000 square meters. We have more than 200 workers, professional technical team, 15 years' experience, exquisite workmanship, stable and reliable quality, competitive price and sufficient production capacity, this is how we make our customers stronger. If you have any inquiry, please do not hesitate to contact us.

The factory has advanced equipment, experienced staffs and good management level, so product quality had assurance, this cooperation is very relaxed and happy!