Aice's Automated Warehouse, Surabaya

Aice is one of the best-known producers of Ice cream in Indonesia. Its production center in Surabaya is set uo with latest cutting-edge technology to strength its productivity. Constant project improvement has always enlarged and adapted to Aice’s business goals and emerging market demands. Currently, the center is equipment with cold storage Automatic Storage and Retrieval System cooperation with robot arms pallet stacking. It fills 5,000 standard pallet in 1500m2 surface area with -20℃.

About Aice

Aice as an ice cream manufacturer entered Indonesia market from 2014, and it just spend two years making its brand the top one in Indonesia. Due to the big influence, this company was honored invited to attend conference with Mr. President.

What does make Aice grow so fast?

The reason is the strict quality control of every manufacturing process, especially the safety of its product. All of Aice production line requires bioclean, including its warehouse. The normal manual warehouse absolutely cannot reach to make the inside environment free from bacteria, due to need large quantity of labor to keep the logistic running. To realize Aice target, ASRS seems to be the best choice.

Full Automatic Operations

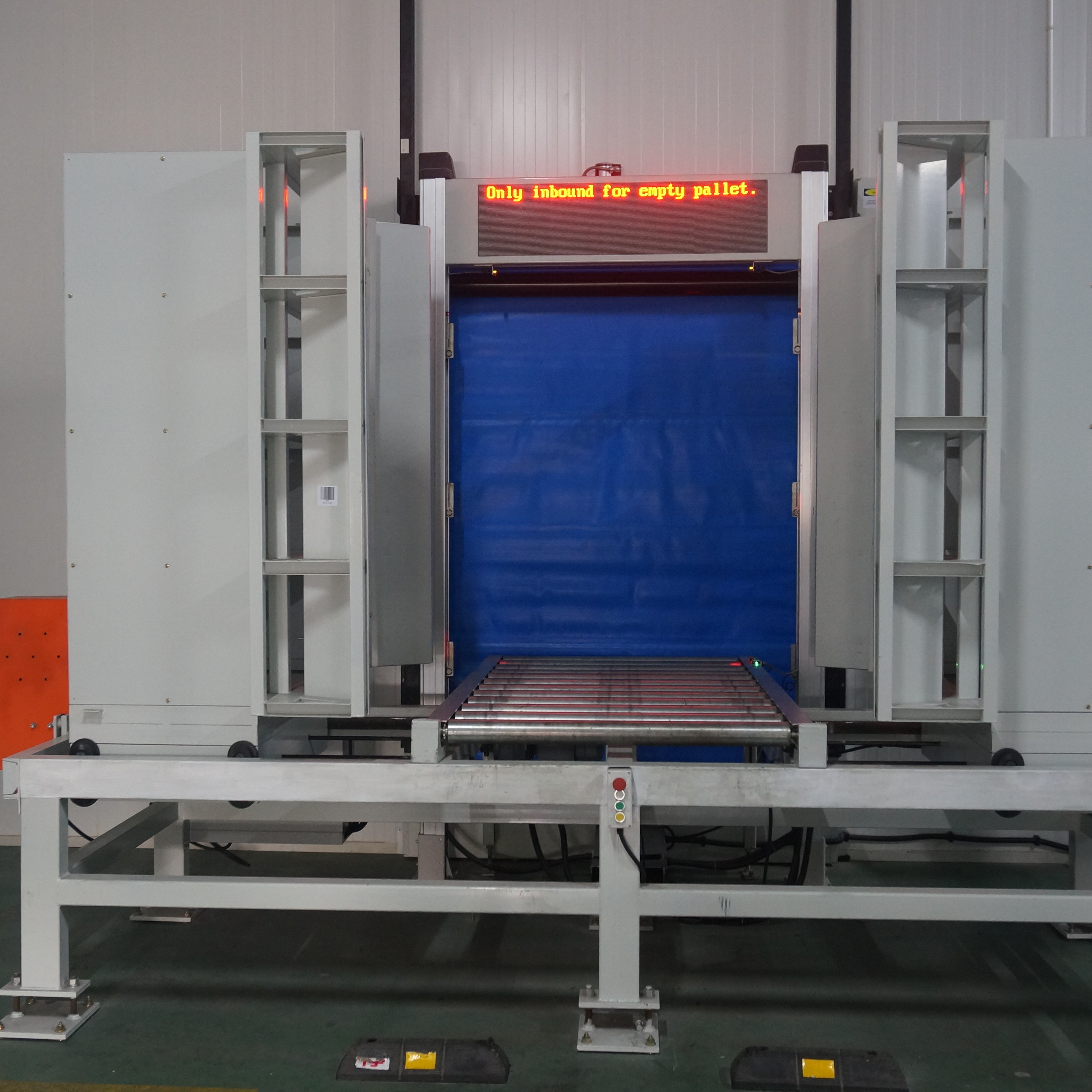

Bearing Aice’s need in mind, Huaruide designed and built an automated warehouse with a capacity for 5,000 standard pallet (1000*1200mm) in -20℃ which is labor-free system. The surface of the installation is 1500m2 and 20 m high right next to the manufacturing center. For that matter, the two buildings are optimally connected together through a tunnel. Once manufacturing center send finished products to automatic warehouse, it can receives and store inside.

The warehouse comprises six. 56 m long aisles with double-deep racking on each side. The finished goods sent by manufacturing center was stacked by robot arms and enter ASRS by conveyors. The warehouse management system(WMS) of Huaruide was installed to distribute the variety of merchandise correctly.

The software is responsible for assigning a location to each product as per their characteristic.

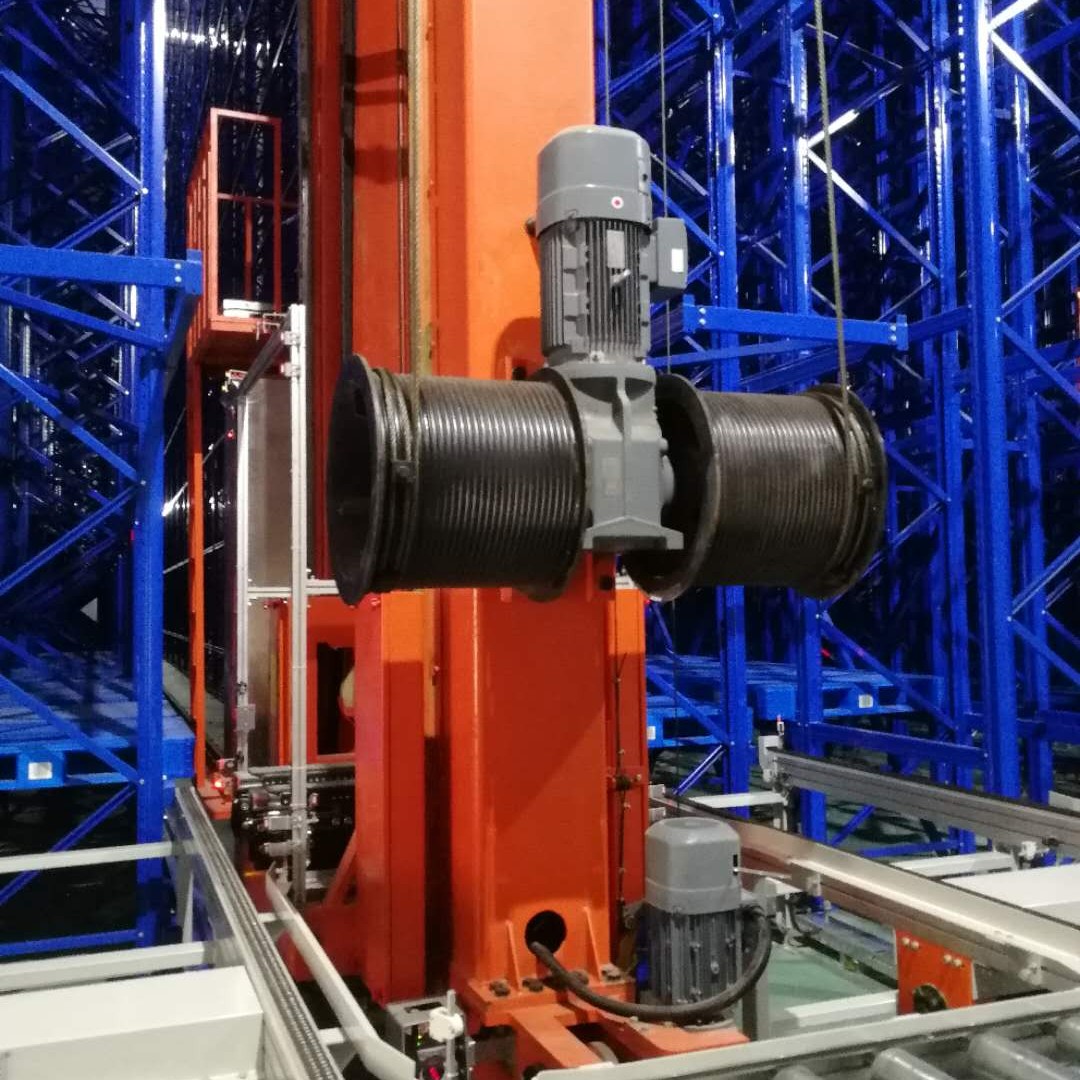

The stacker cranes run inputs and outputs of the goods from the items’ corresponding locations, according to the WMS’s instructions. They operate at a travel speed of 160 m/min and 60 m/min when in a lifted position. Each one of these machines can produce 24 combined cycles (24 pallets in and 24 pallets out).

Automating all processes has brought about significant gains for Aice. With usage of Huaruide ASRS, the palletizing, storage and retrieval becomes automatically. Fully make labor-free in storage process.

Save Energy

Due to it is a cold storage warehouse, each time of open heat insulation door means energy lost. Compared with manual one which need labors work inside, Huaruide WMS will arrange the best outgoing strategy according to waves and reducing the frequency of opening doors. This WMS will collect the order and calculate a method to outgoing with inside logic which is under discussion with customers.

Advantages for Aice

The safest storage environment:For Aice, there is nothing important than product quality, food safety is a factor of quality. Huaruide automatic storage and retrieval system providing labor-free environment and realize sterile meet customer’s need.

The maximum utilization of limited surface place: in 1,500 m2, Aice has a fully automated solution for 5,000 pallets, and each weighing up to 500 kg.

Top productivity: all warehouse operations are fully automatic. In doing so, it ensures the inflows and outflows that Aice needs to supply its customers.

Increased security: automation means operators are not required to handle the goods, which prevents errors and guarantees a high level of security.

Gallery

Aice Double Deep Stackcer Crane with Robot Arms Palletizeing, Surabaya

| Storage Capacity | 5, 000pp |

| Height | 20m |

| Type | Stand-alone Cold Storage ASRS |

| Pallet Size | 1200*1000 |

| Stacker Crane Aisle | 6 |

| Throughput | 50 pallet/hour |

Post time: Jul-13-2021