Jingxi Pharmaceuticals High-density Solution, Xi'an

The Jingxi Pharmaceuticals automated warehouse in Xi’an (China), in operation since 2016, has a storage capacity of more than 25,190 standard pallet (1000*1200mm). It was equipped with high-density storage system, served by mother-child shuttle, lift, and conveyor circuit, in addition to picking are at the front of the warehouse. All operations are controlled and directed via the Huaruide WMS warehouse management system.

Needs of Jingxi Pharmaceuticals

Jingxi is a rasing star in China pharmaceuticals industry, it started from 2007, and occupy big marker share now. It has always been committed to innovation, sustainability and the quest for the best solution designed to satisfy current and future need of society.

To facing the rapid growth of business in the last few years, and most safe environment to store produced medicine, the company required a warehouse with sufficient capacity to deal these needs in the smallest surface area.

The customer also requests a prefer tracking system for finished goods, according to government, regulations.

This automatic installation proposed by Huaruide was the 15.6m racking high stand-alone warehouse, located next to manufacturing facility whose function for Meishan Iron is to store space pare for production facility. It comprised five aisles, in which three straight double-deep stacker cane and one u-turning stacker crane move on their own rail, handling the four sizes of pallets stored in racks. Huaruide WMS assigns defined locations for certain pallets. Thanks for the optimal space utilization, the Meishan Iron warehouse has a storage capacity of 11, 300 pallets in 3600m2.

The Jingxi Pharmaceuticals Automation Options

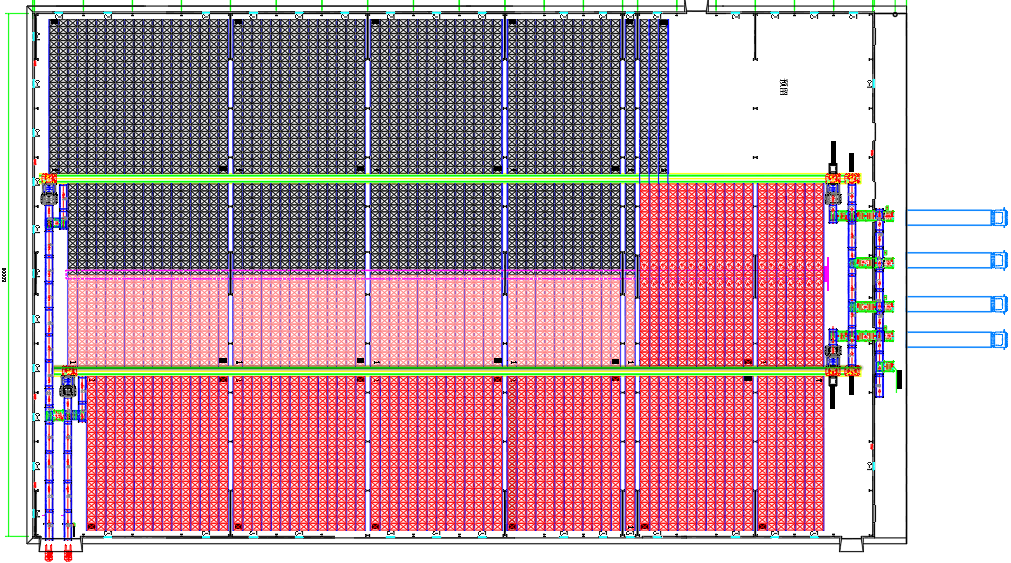

Huaruide designed, manufacturing and implement a 10,000 m2 high-density storage mother-child shuttle warehouse in 2016 measuring 128 m long, 80 m wide and 12m high, and until now, it is still the biggest high-density storage warehouse in Asia. It comprise of two mother shuttle aisle with five layers, three multi-deep shuttle type racks on their sides, which are twenty-two, twenty-five and twenty-two deep of each row. More than 25, 000 pallets are stored in this installation and the distance between two adjacent pallets are less than 50 mm in the same row without losing any storage space.

Each aisle is served by a mother-child shuttle that picks up pallets from lift, mother shuttle move to defined row and child shuttle deposits pallets in the location that has been assigned by Huaruide WMS warehouse management system, the pallet come from incoming conveyor. Later, they perform the same movement but in reverse of outgoing goods.

The Layout of Jingxi High-density Storage System

Incoming and Outgoing Goods

The operations in the warehouse is perfect because of their simplicity: the receipt and dispatch of goods is carried out automatically at the front of the warehouse via a conveyor circuit with rollers and chains that controls the pallets at all times. This system allows goods to be moved independently, without the need for human intervention, and prevents logistical errors. Both processes are separated to avoid interference.

Before entering the automated warehouse, goods must pass through the checkpoint to validate that they fulfil the requirements established for their location in the warehouse. Pallets that do not pass inspection are deposited on the rejects conveyor, placed in parallel, for their reconditioning.

The Picking and Partial Palletizing Station

There are four picking stations and one partial palletizing station were also placed. The operators take the goods from pallet according to orders and push the button once picking finished. The pallets are sent back to rack by cooperation of conveyors, lift, and mother-child shuttle, and the outbound goods will be place on pallet first and taken out by forklift later on.

Once Huaruide WMS monitor a pallet which load very less goods, it will be outbound to partial palletizing station where the pallet should be re-palletized and sent back to rack or outbound directly.

Warehouse Management Software

Huaruide WMS is a powerful warehouse management system whose purpose is to coordinate and manage all internal operations. The functions it performs include reception, the allocation of locations and storage of pallet order preparation and final dispatch.

The WMS is in permanent and bidirectional communication with the ERP, transferring data and information to itself to operate and manage the warehouse effectively and to obtain maximum profitability from the logistics processes.

Advantages for Jingxi Pharmaceuticals

Large capacity: Jinxi’s high density storage project has a capacity to locate more than 25,000 pallets in 10, 240 m2.

Maximum agility: operations are very simple, lithe and completely automated, minimising human intervention.

Optimal management: the warehouse is controlled by the Huaruide warehouse management system in order to optimize all the movements and operational processes that take place.

Gallery

Jingxi Pharmaceuticals High-density Solution, Xi'an

| Storage Capacity | 25,190pp |

| Height | 12m |

| Type | Stand-alone mother-child shuttle |

| Pallet Size | 1200*1000 |

| Mother-child shuttle Aisle | 2 aisle/5 layers/totally 10 sets |

| Throughput Requirement | 400 pallet/hr |

Video

Post time: Jul-14-2021